Menu

SPIDER Resin™ is designed for use in indoor/outdoor applications for coatings requiring low toxicity,

durability and water resistance properties.

SPIDER Resin™ is a patent pending, modified resin that has zero VOC and zero BPA/F.

SPIDER Resin™ when combined with hardener, creates an Isocyanate free Polyurethane resin system. SPIDER Resin™

designed for indoor/outdoor applications for coatings requiring low toxicity, durability and water resistance.

SPIDER Resin™ complies with REACH guidelines to be classified as a Polymer.

• Zero BPA/F (without endocrine disruptors) • Zero isocyanate Polyurethane • Zero VOC • 100% active matter without solvents • Good moisture and chemical resistance • Excellent adhesion properties especially on wet surfaces or in humid conditions

• High impact and tensile strength • High gloss and color retention • Increased abrasion resistance • Elongation: < 1-3% elongation • Low viscosity • Easy cleaning • No ADR transport regulation for road transport (resin only).

• Zero BPA/F (without endocrine disruptors)

• Zero isocyanate Polyurethane

• Zero VOC

• 100% active matter without solvents

• Good moisture and chemical resistance

• Excellent adhesion properties especially on wet surfaces or in humid conditions

• High impact and tensile strength • High gloss and color retention

• Increased abrasion resistance

• Elongation: < 1-3% elongation

• Low viscosity • Easy cleaning

• No ADR transport regulation for road transport (resin only).

| Sulfuric acid 10% H2SO4 | Gloss reduction |

| Sodium hydroxide 10% NaOH | No effect |

| Motor oil | No effect |

| Brake fluid | No effect |

| Aviation hydraulic fluid | No effect |

| Shore D Hardness | 42 – 90 |

| Tensile strength | 16 MPa |

| Elongation | 62% |

| 180 Bend test | Pass |

– “Spider Resin” samples Part A & Part B.

– Small mix prepared using 100 Part A to 35 Part B by weight

-mix ratio Drawdown @ 100 micron – gloss 90.9%.

– Drying time @ 75 micron – approx. 5.5 to 6 hour.

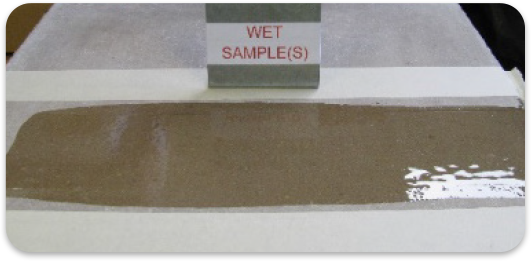

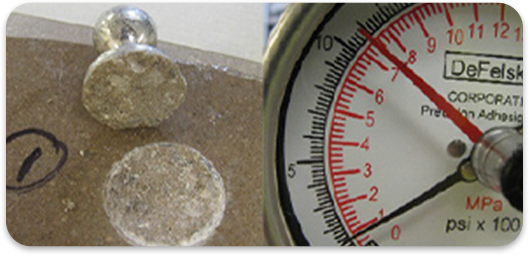

Concrete paving slab – top surface abraded with grind

stone to remove excess laitance, dampened to remove

residual dust and left to dry overnight

Another mix of resin prepared and applied to concrete @ 100

micron and left to cure over weekend

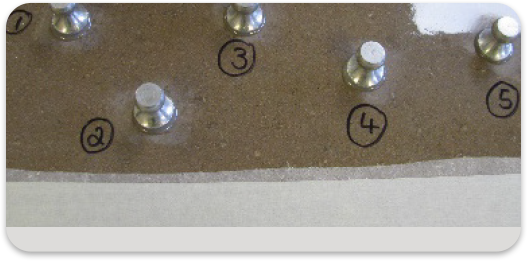

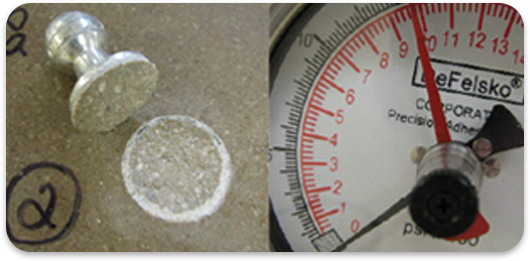

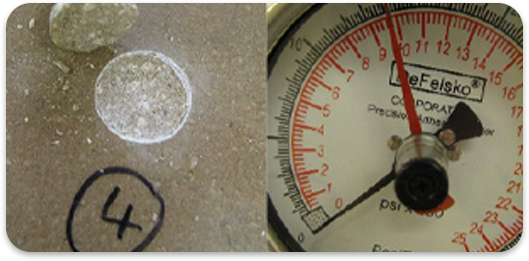

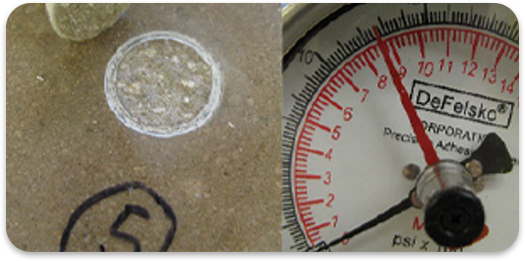

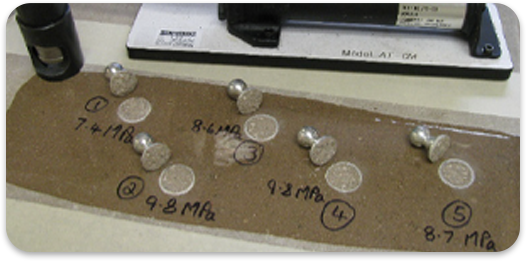

Surface of resin film and of 5 x 20mm pull-off dollies prepared,

before dollies applied to resin film using Araldite Rapid adhesive.

Left to cure for 4 days

Using 20mm cutting tool, the coating around the edges of the

dollies were cut through, and excess adhesive and debris

removed

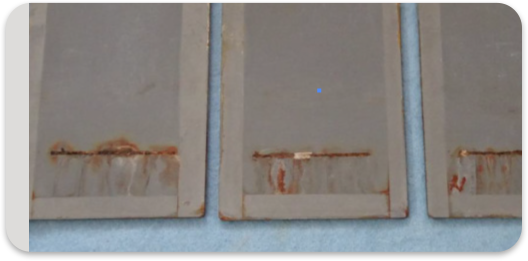

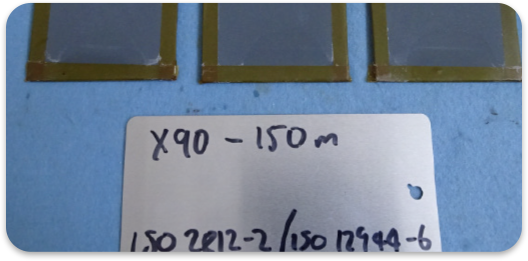

80 Micron Plate after C5HZX90-80 Micron

-IS to 9227 -1440 hours -C5H

80 Micron Plate after IM3 – 4000 Hours

Salt water immersion Test

Dollies then removed using DeFelsko AT-CM Adhesion Tester Pressure Gauge, in accordance with ASTM D7234:19

Dolly 1 – 7.4 MPa

Dolly 2 – 9.8 MPa

Dolly 3 – 8.6 MPa

Dolly 4 – 9.8 MPa

Dolly 5 – 8.7 MPa

Average – 8.86 MPa

Copyright 2022 Spider Resin. All rights reserved